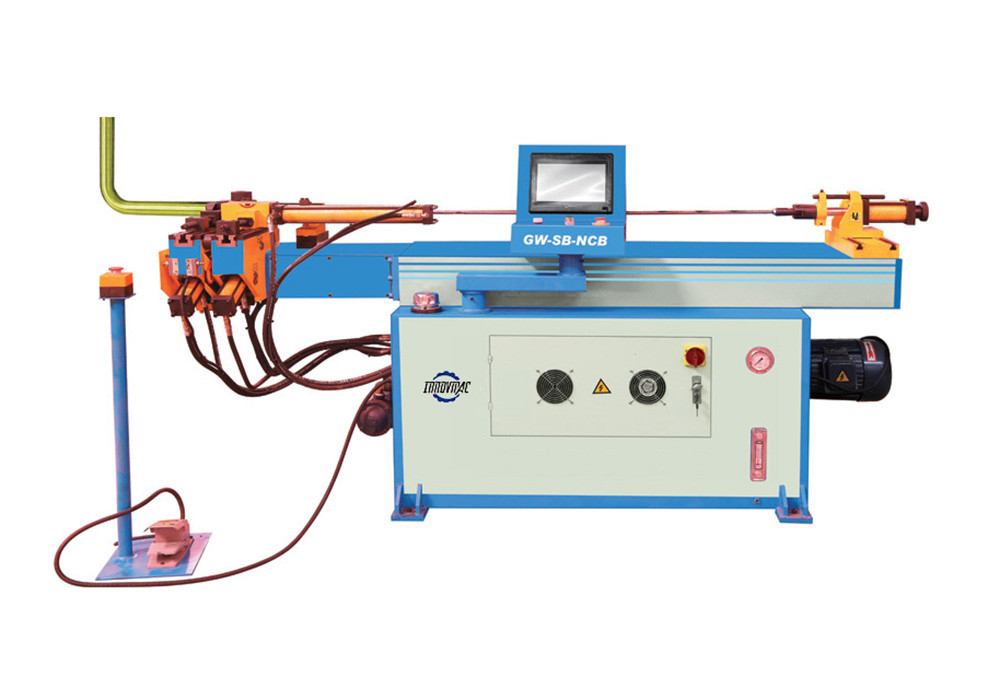

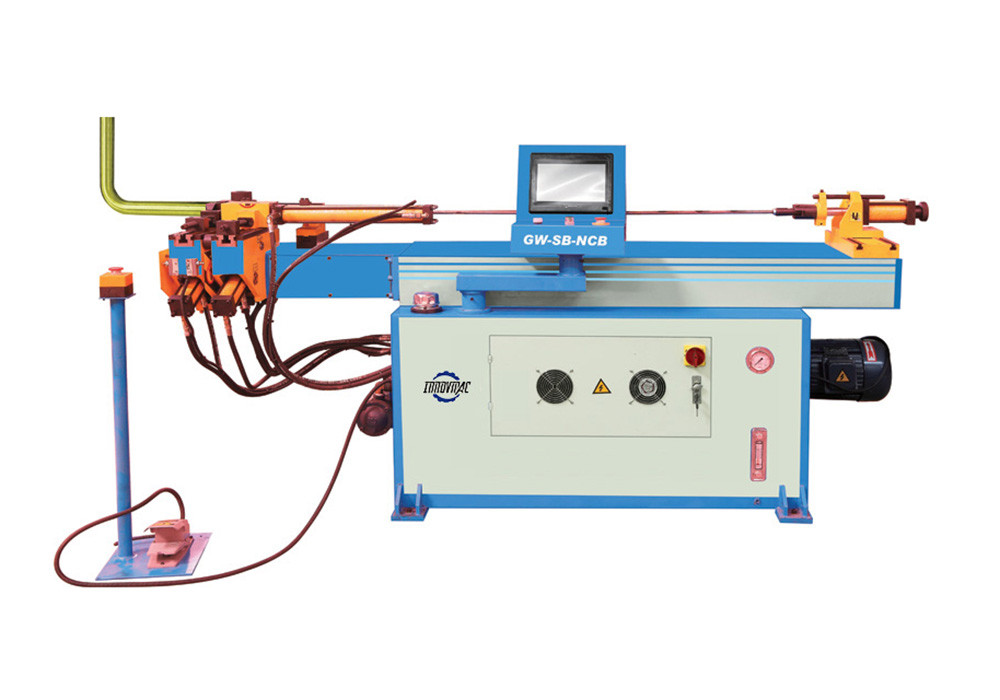

GM-SB-NCB

Characteristics of Pipe Bending Machine:

It adopts imported special controlling system. The action of the machine is stable. It has mode of manual and auto, the operator can change the Programs.This series is suitable for two-dimensional bending at high speed and in mass production.

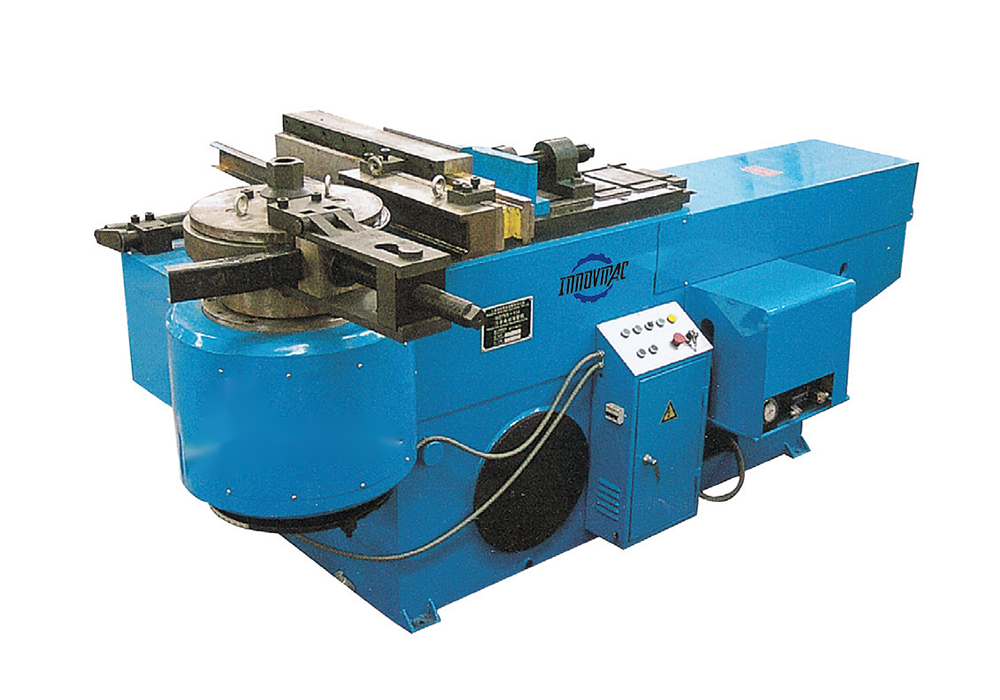

GM-SB-NCBA

Characteristics of Pipe Bending Machine:

It adopts imported special controlling system, which can continously rotate the positioner from 0 degree to 360 degrees automatically in threedimensional space driven by servo motor.

It is suitable for processing high precision complex fittings. In the touch screen, operator can set and change the rotating angle, bending angle easily.

Model | Unit | 18NCB | 28NCB | 38NCB | 42NCB | 50NCB | 63NCB | 76NCB | 89NCB | 100NCB | 114NCB | 120NCB | 129NCB | 140NCB | 159NCB | 168NCB | 219NCB | 273NCB | 325NCB |

Max. Bending Capacity | mm | ¢18×2 | ¢28×2 | ¢38×2 | ¢42×3 | ¢50×2 | ¢63×4 | ¢76×5 | ¢89×10 | ¢100×8 | ¢114×12 | ¢120×10 | ¢129×14 | ¢140×14 | ¢159×18 | ¢168×18 | ¢219×18 | ¢273×20 | ¢325×25 |

Bending Radius Region | mm | 20-150 | 20-180 | 20-200 | 20-250 | 20-250 | 25-350 | 30-350 | 40-400 | 40-400 | 40-450 | 40-450 | 50-550 | 50-600 | 60-700 | 60-700 | 80-1000 | 150-1250 | 200-1500 |

Bending Angle Region | Degree | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 |

Effective Length Over Mandrel | mm | 2000 | 2000 | 2000 | 2200 | 2200 | 2500 | 3200 | 4000 | 4000 | 4200 | 4200 | 4200 | 4200 | 5600 | 5600 | 6500 | 7500 | 8000 |

Oil Pressure System Motor | kw | 2.2 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 30 | 45 | 55 |

Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

Machine Dimension | mm | 2300×550×1300 | 2500×650×1300 | 2500×700×1300 | 3000×800×1300 | 3000×800×1300 | 4200×1200×1350 | 5000×1200×1350 | 5300×1350×1200 | 5300×1350×1200 | 5300×1350×1300 | 5300×1350×1200 | 5300×1350×1300 | 6500×1350×1300 | 7200×2000×1400 | 7200×2000×1400 | 9000×2000×1400 | 13000×4000×2500 | 14000×4500×2500 |

Machine Weight | kg | 1000 | 1300 | 1500 | 1800 | 1800 | 2500 | 3000 | 4000 | 4500 | 5000 | 5500 | 6500 | 8500 | 12000 | 12500 | 22000 | 35000 | 56000 |

Model | Unit | 18NCBA | 28NCBA | 38NCBA | 42NCBA | 50NCBA | 63NCBA | 76NCBA | 89NCBA | 100NCBA | 114NCBA | 120NCBA | 129NCBA | 140NCBA | 159NCBA | 168NCBA | 219NCBA | 273NCBA | 325NCBA |

Max. Bending Capacity | mm | ¢18×2 | ¢28×2 | ¢38×2 | ¢42×2.5 | ¢50×2 | ¢63×4 | ¢76×4 | ¢89×8 | ¢100×6 | ¢114×8 | ¢120×6 | ¢129×10 | ¢140×12 | ¢159×16 | ¢168×18 | ¢219×18 | ¢273×18 | ¢325×22 |

Bending Radius Region | mm | 20-150 | 20-180 | 20-200 | 20-250 | 20-250 | 25-350 | 30-350 | 40-400 | 40-400 | 40-450 | 40-450 | 50-550 | 50-600 | 60-700 | 60-700 | 80-1000 | 150-1000 | 200-1100 |

Bending Angle Region | Degree | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 | 0-190 |

Effective Length Over Mandrel | mm | 2000 | 2000 | 2400 | 2400 | 2400 | 2600 | 2600 | 3000 | 3000 | 3200 | 3200 | 3500 | 3500 | 4500 | 4500 | 5000 | 6000 | 6000 |

Oil Pressure System Motor | kw | 2.2 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 30 | 45 | 55 |

Max. Pressure | kg/cm | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

Machine Dimension | mm | 3500×550×1300 | 3800×650×1300 | 4000×700×1300 | 4000×700×1300 | 4000×800×1300 | 5000×1200×1350 | 5000×1200×1350 | 5500×1350×1200 | 5500×1350×1200 | 6500×1350×1300 | 6500×1350×1300 | 7500×1350×1300 | 7500×1350×1300 | 7200×2000×1400 | 8000×2000×1400 | 9000×2200×1400 | 13000×4000×2500 | 14000×4500×2500 |

Machine Weight | kg | 1300 | 1500 | 2000 | 2200 | 2200 | 3000 | 3500 | 4800 | 5000 | 5500 | 6000 | 7000 | 9000 | 12000 | 13000 | 24000 | 38000 | 58000 |

- Metal Cutting Machine

- Metal Forming Machine