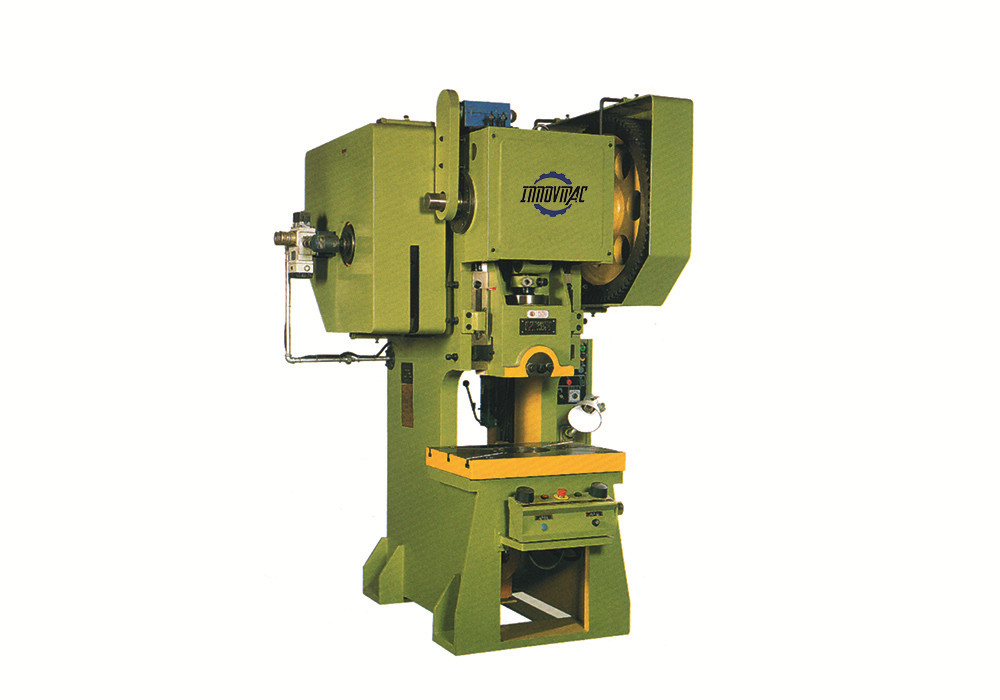

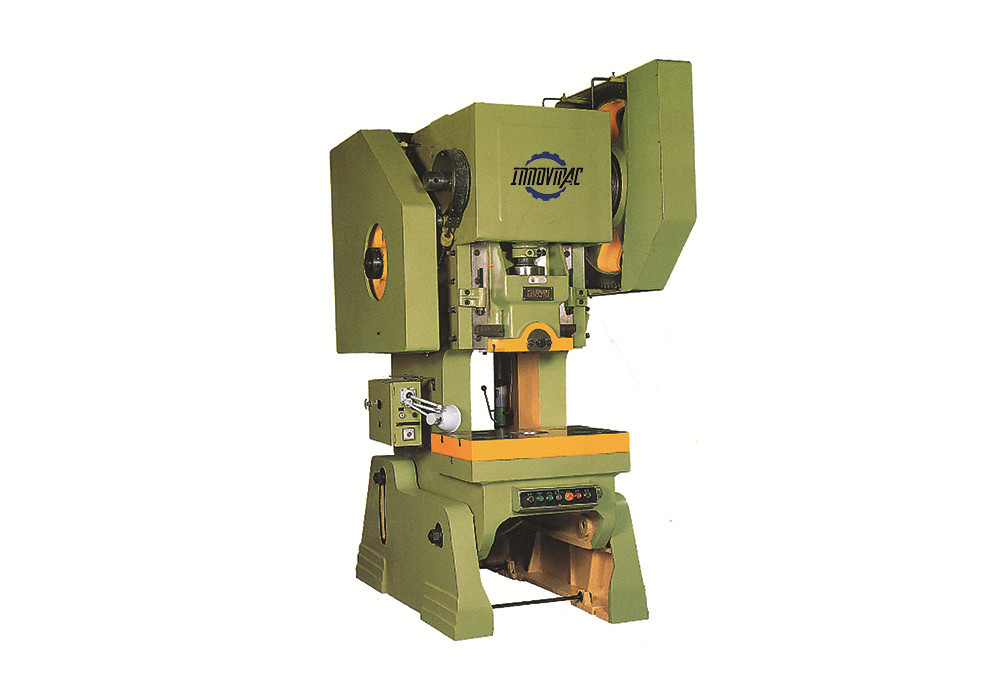

With the optimization design, used high-grade alloy steel, double crank, two wide work centers with connection bar structure.

In order to guarantee the machine running in stable and smooth, adopts the design of symmetrical boards with balancer.

The precision of mold adjusting up to 0.1mm, safety, reliable and convenient.

Crank, gear, connect bar are oxidized hardening and milled, having super comprehensive mechanical performance and durable function.

Used reliable high sensitive clutch/brake and international up-to-date twin electromagnetic valve, overloading protector can guarantee the precision of slider running and stop and safe production of the machine.

Reasonable structural design, is benefit for automation production and reduce cost, improve efficiency.

Advanced design principle, low noise, low consumption, low cost, save energy.

Name | Unit | APC-110 | APC-160 | APC-200 | APC-250 | ||||

Model | V | H | V | H | V | H | V | H | |

Capacity | Ton | 110 | 160 | 200 | 250 | ||||

Rated tonnage point | mm | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 |

Stroke | mm | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 |

Stable speed | s.p.m | 35-65 | 50-100 | 30-55 | 40-85 | 25-45 | 35-70 | 20-35 | 30-60 |

Die height | mm | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 |

Slide adjustment | mm | 100 | 100 | 120 | 120 | ||||

Bolster area | mm | 1800x650x130 | 2000x760x150 | 2400x840x170 | 2700x900x170 | ||||

Slide area | mm | 1400x500x70 | 1600x550x70 | 1850x650x95 | 2100x700x95 | ||||

Main motor | kwxP | 11x4 | 15x4 | 18.5x4 | 22x4 | ||||

Presses weight | Ton | 14.2 | 20 | 27.5 | 45.5 | ||||

Air pressure | kg/cm2 | 5 | 5 | 5 | 5 | ||||

Presses precision | JIS(CNS)1 class | ||||||||

Die cushion capacity | Two plate&two cylinders | ||||||||

Capacity | Ton | 3.6x2 | 6.3x2 | 10x2 | 14x2 | ||||

Air pressure | kg/cm2 | 6 | 6 | 6 | 6 | ||||

Stroke | mm | 70 | 70 | 80 | 100 | ||||

Die cushion work part dimension | mm2 | 350x235x2 | 410x260x2 | 540x350x2 | 640x470x2 | ||||

- Metal Cutting Machine

- Metal Forming Machine