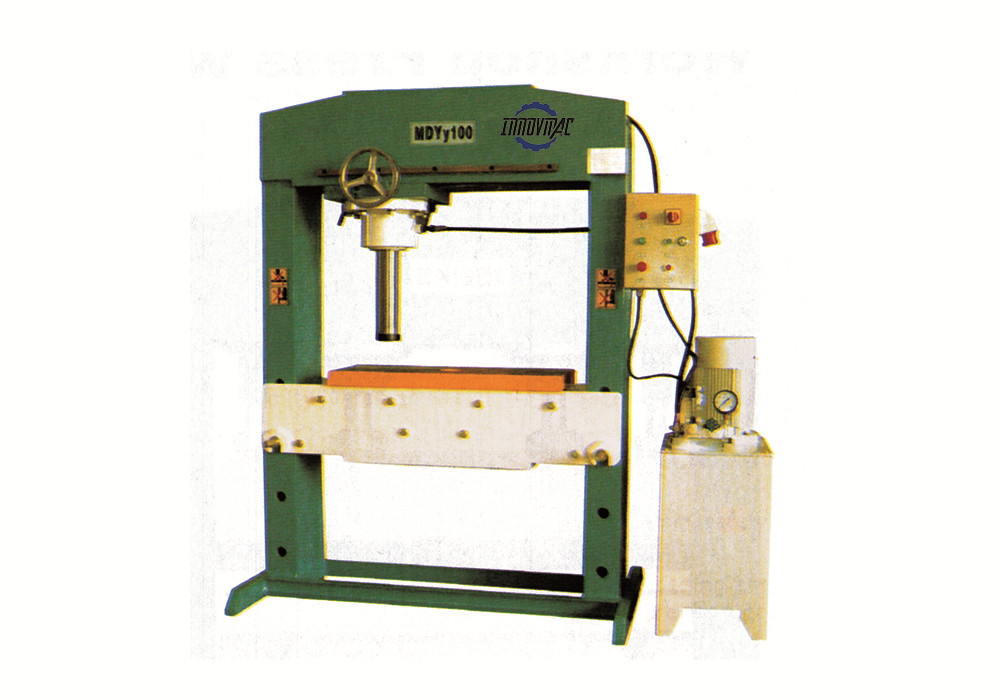

The hydraulic control system employs cartridge valve integrated system, so the moving is reliable and can work for a long life. With an independent power-control system, this hydraulic press has a very clear working circle and can be easily repaired. The working pressure and stroke can be changed according to customer’s needs.

This series hydraulic press is widely applied in various forming technology, including the processing and forming of various plastic material such as extrusion, bending, ruffled, deep drawing, etc.; also can be used for all kinds of press forming of plastic, powder products.

Hydraulic press is suitable for pressing operations such as punching, pressing, stamping, bending, flanging and extrusion etc. It is also used for straightening, pressure assembling and molding of powder products as well as nonmetal materials such as plastics, insulator and abrasive products etc...This press, with independent motive organization and electric system, adopts the control system of the centralized buttons, and controls technical operations with the relay to achieve adjustment (inching) and operation (semi-auto).

Mechanical press is widely used in telecommunication equipments, instruments and meters, electric appliances, clocks and watches, toys, hardware, tractors, automobile and aviation industry and so on. The presses can be used for punching, dropping material, bending and light extension, etc. because of the large size of table, the presses can be employed for stamping of large sheet, stamping mould assembly lines, and the mold for stamping and progressive punching, etc.

Model | Unit | YQ32-40 | YQ32-63 | YQ32-100 | YQ32-100A | YQ32-160 | YQ32-160B | YQ32-200 | YQ32-200A | YQ32-315 | YQ32-315B | YQ32-400 | YQ32-500 | YQ32-500C | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

Rated Pressure | KN | 400 | 630 | 1000 | 1000 | 1600 | 1600 | 2000 | 2000 | 3150 | 3150 | 4000 | 5000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

Maximum Pressure Of Liquid | MPA | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

Knock-out Pressure | KN | 120 | 190 | 190 | 190 | 400 | 400 | 400 | 400 | 630 | 630 | 630 | 1000 | 1000 | 1000 | 1600 | 1600 | 1600 | 2000 |

Stroke of Slide | mm | 450 | 500 | 600 | 600 | 700 | 700 | 700 | 700 | 800 | 800 | 800 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Stroke of Knock-out | mm | 150 | 200 | 200 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 350 | 350 | 350 | 400 | 400 |

Daylight | mm | 750 | 750 | 880 | 880 | 1000 | 1000 | 1100 | 1100 | 1250 | 1250 | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

Speed of Slide Descent | mm/s | 160 | 180 | 120 | 120 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 80 | 80 | 80 | 80 | 80 |

Pressing | mm/s | 20-25 | 15-20 | 10-14 | 10-14 | 10-15 | 10-15 | 10-15 | 10-15 | 8-12 | 8-12 | 6-10 | 10-15 | 10-15 | 6-10 | 12-15 | 10-15 | 10-15 | 10-15 |

Return | mm/s | 120 | 100 | 120 | 120 | 70 | 70 | 70 | 70 | 60 | 60 | 55 | 70 | 70 | 60 | 70 | 70 | 70 | 70 |

Size of Table L-R | mm | 500 | 580 | 720 | 1000 | 720 | 1000 | 1000 | 1260 | 1260 | 1400 | 1240 | 1400 | 2400 | 1500 | 1600 | 1600 | 1700 | 1600 |

F-B | mm | 460 | 500 | 580 | 800 | 620 | 800 | 900 | 1200 | 1200 | 1400 | 1200 | 1400 | 1400 | 1500 | 1600 | 1600 | 1600 | 1600 |

- Metal Cutting Machine

- Metal Forming Machine