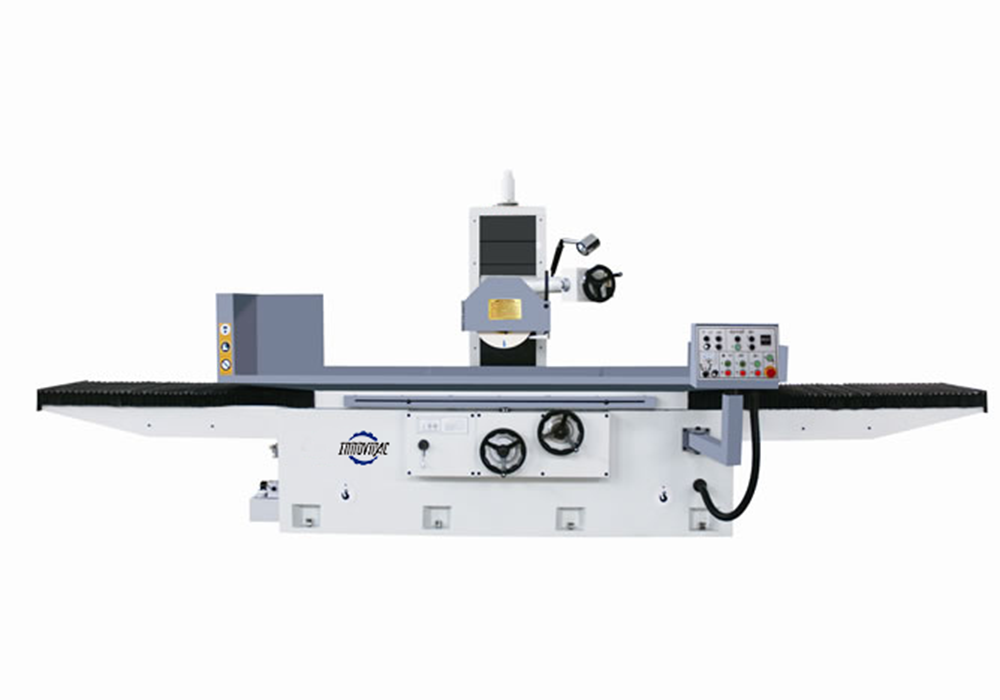

M618A

The main parts of machine such as base, column & saddle are made of high grade casting which are stress released by annealing to ensure stable rigidity and high accuracy and to extend machine life.Slideways (ball way or turcite ways)

Both longitudinal & double – V cross sildeways are precisely handscrapted and laminated with TURCITE-B providing a smooth movement and ever low wearing, mostly suitable for FORMING grinding.

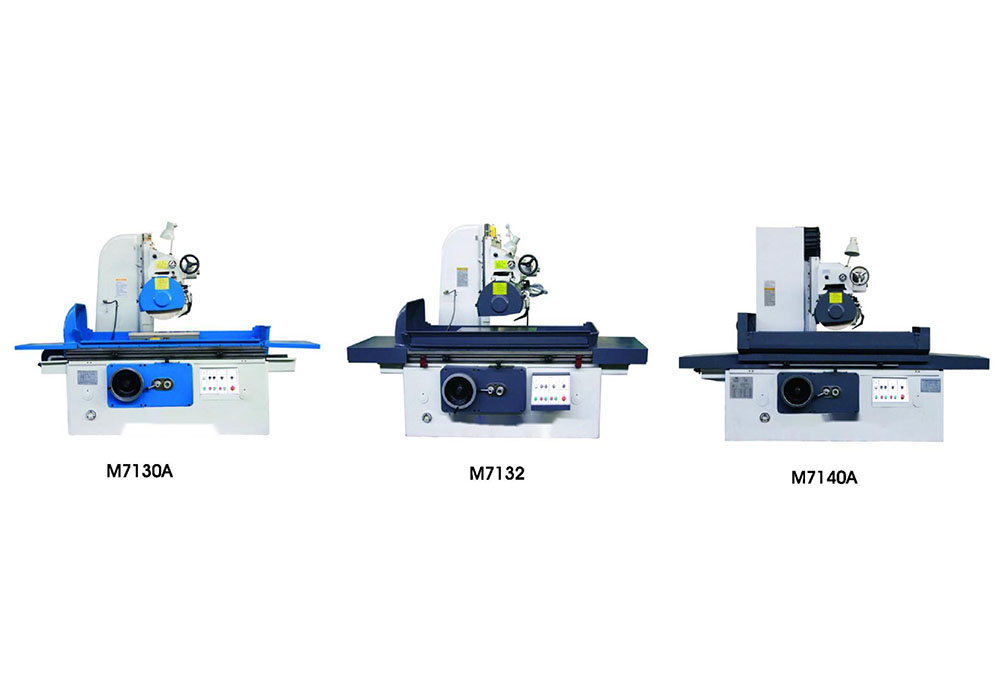

M250

The automatic lubrication system is furnished as standard to provide ample lubrication on all slideways and lead-screws enabling a smooth movement so as to minimize wearing possibility.

Model | units | M618A | M250 |

Max.Size Of Workpiece Be Ground (L×W×H) | mm | 500×190×335 | 600×280×450 |

Max. Grinding Length | mm | 500 | 600 |

Max. Grinding Width | mm | 190 | 280 |

Distance From Table Surface ToSpindle Center | mm | 335 | 450 |

Max Loading Capacity | Kg | 200 | 150 |

Table Size (L×W) | mm | 460×180 | 540×250 |

Number Of T-Slot | mm×n | 12×1 | 12×1 |

Speed OF Working Table | m/min | 3-23 | 3-23 |

Cross Feed On Handwheel | mm | 0.02/Graduation 2.5/revolution | 0.02/Graduation |

Vertical Feed On Handwheel | mm | 0.01/Gradution 1.25/revolution | 0.01/Gradution 1.25/revolution |

Wheel Size (dia.×width×bore ) | mm | 180×12×31.75 | 200×20×31.75 |

Spindl Speeds 50HZ | rpm | 2850 | 2850 |

Spindle Moto | Kw | 1.1 | 1.5 |

Coolant Pump | Kw | 0.24 | 0.4 |

Machine Size(L×W×H) | mm | 1100×1020×1800 | 1450×1350×1960 |

Gross、Net(weight) | T | 0.70、 0.65 | 1.00、 0.90 |

- Metal Cutting Machine

- Metal Forming Machine